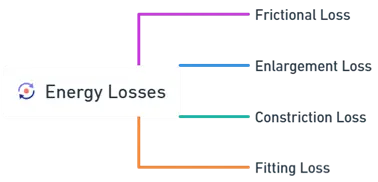

- Energy losses during the flow of fluid through a system occur due to various factors.

- Here are the main types of losses:

Advertisements

-

Frictional Loss:

- Occurs due to the friction between the fluid and the pipe walls.

- Depends on the flow velocity, pipe diameter, fluid viscosity, and pipe roughness.

- Calculated using the Darcy-Weisbach equation:

-

$h_f = f \cdot \frac{L}{D} \cdot \frac{v^2}{2g}$

-

- hf = head loss due to friction

- f = friction factor

- L = length of the pipe

- D = diameter of the pipe

- v = flow velocity

- g = acceleration due to gravity

-

-

Enlargement Loss:

- Occurs when the fluid flows from a smaller pipe to a larger pipe.

- The sudden increase in cross-sectional area causes a drop in velocity and kinetic energy, resulting in energy loss.

- Expressed as:

-

$h_e = K_e \cdot \frac{v_1^2}{2g}$

-

- he = head loss due to enlargement

- Ke = loss coefficient for enlargement

- v1 = velocity in the smaller pipe

-

Advertisements

-

Constriction Loss:

- Occurs when the fluid flows from a larger pipe to a smaller pipe.

- The sudden decrease in cross-sectional area causes an increase in velocity, leading to turbulence and energy loss.

- Expressed as:

-

$h_c = K_c \cdot \frac{v_2^2}{2g}$

- hc = head loss due to constriction

- Kc = loss coefficient for constriction

- v2 = velocity in the smaller pipe

-

Fitting Loss:

Advertisements

- Occurs due to the presence of fittings like elbows, tees, valves, and other components in the piping system.

- Each fitting introduces additional resistance and turbulence, causing energy loss.

- Expressed as:

-

$h_{\text{fitting}} = K_f \cdot \frac{v^2}{2g}$

- Hfittings = head loss due to fittings

- Kf = loss coefficient for the fitting

- v = flow velocity

- These losses collectively contribute to the overall energy loss in a fluid flow system, impacting the efficiency and performance of fluid transport.