- Heat Interchangers and Heat Exchangers are terms often used interchangeably, but they typically refer to the same concept: devices that transfer heat between two or more fluids.

Heat Interchangers

Terminology

- The term “heat interchanger” is less common.

- It typically refers to a device specifically designed for exchanging heat between process streams within an industrial setup, focusing on energy efficiency and seamless integration into the process flow.

Principle and Construction

- Heat interchangers operate on the same principle as heat exchangers: transferring heat from a hotter fluid to a cooler one.

- Their construction is usually similar to standard heat exchangers (e.g., shell-and-tube, double-pipe), but they may be optimized for particular industrial process requirements.

Applications

- Commonly found in chemical plants, refineries, and other integrated industrial systems where maximizing heat recovery and minimizing energy consumption are essential.

Heat Exchangers

Principle:

- Heat exchangers transfer thermal energy from one fluid to another without mixing the fluids.

- They can operate with liquids, gases, or both, and the fluids can be either in direct contact or separated by a solid wall.

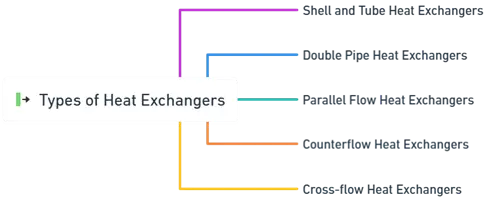

Types of Heat Exchangers (Based on Construction):

-

Shell and Tube Heat Exchangers:

- Construction: Composed of a series of tubes, one set carrying the hot fluid and the other carrying the cold fluid, enclosed within a cylindrical shell.

- Working: Heat is transferred from the hot fluid inside the tubes to the cold fluid outside the tubes (or vice versa).

- Applications: Power plants, oil refineries, and chemical processing.

-

Double Pipe Heat Exchangers:

- Construction: Two concentric pipes, with one fluid flowing through the inner pipe and the other fluid flowing through the annular space between the pipes.

- Working: Heat transfer occurs between the fluids through the wall of the inner pipe.

- Applications: Small-scale industrial processes and laboratory setups.

Types of Heat Exchangers (Based on Flow Arrangement)

-

Parallel Flow Heat Exchangers:

- Description: Both fluids enter the heat exchanger at the same end and move in parallel.

- Efficiency: Suitable for moderate temperature differences.

- Example: Some chemical reactors.

-

Counterflow Heat Exchangers:

- Description: Fluids enter the heat exchanger from opposite ends and flow in opposite directions.

- Efficiency: More efficient than parallel flow, achieving a larger temperature gradient.

- Example: Steam condensers, economizers.

-

Crossflow Heat Exchangers:

- Description: Fluids move perpendicular to each other.

- Efficiency: Suitable for applications with limited space.

- Example: Car radiators, air handling units.

Applications of Heat Exchangers

- Power Generation: Steam generators, condensers, and feedwater heaters in thermal power plants.

- HVAC Systems: Heating, ventilation, and air conditioning units for residential and commercial buildings.

- Chemical Processing: Reactors, distillation columns, and evaporators in chemical plants.

- Food and Beverage: Pasteurization, sterilization, and cooling processes.

- Automotive: Radiators and oil coolers in vehicles.

- Refrigeration: Evaporators and condensers in refrigeration and air conditioning systems.