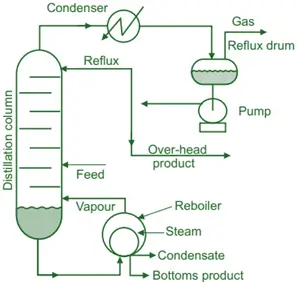

Principle of Molecular Distillation:

- Molecular distillation is a type of vacuum distillation performed at extremely low pressures, allowing the distillation of high molecular weight, thermally unstable compounds.

- It involves a short path between the evaporator and the condenser.

Methodology of Molecular Distillation:

Advertisements

- Setup: Includes a high vacuum system, short-path distillation apparatus, and a cold trap.

- Pressure Reduction: The pressure is reduced to very low levels using a high vacuum pump.

- Heating: The mixture is gently heated.

- Short Path Distillation: The molecules travel a short distance to the condenser, minimizing thermal decomposition.

- Collection: The distilled components are collected in the cold trap.

Mean Free Path of Molecules

- The mean free path is the average distance a molecule travels between collisions with other molecules.

- In molecular distillation, the pressure is reduced to the extent that the mean free path of the molecules becomes comparable to the distance between the evaporator and the condenser surfaces.

- This minimizes the chances of molecular collisions, enabling molecules to travel directly from the heated surface to the condenser without interacting with other molecules.

Advertisements

Types of Molecular Distillation Apparatus

Falling Film Molecular Distillation

- Structure: A cylindrical column where the liquid flows down a heated vertical surface, forming a thin film.

- Operation: The heated surface causes volatile components to evaporate. These molecules then travel through a vacuum to a condenser.

- Advantages: Simple to operate and maintain, with high thermal efficiency and minimal thermal degradation.

- Applications: Widely used in the purification of heat-sensitive substances such as vitamins, essential oils, and pharmaceuticals.

Centrifugal Molecular Distillation

- Structure: A rotating disk or cone where the liquid is spread as a thin film, maintained by centrifugal force.

- Operation: The rotation ensures even distribution and optimal film thickness. The volatile components evaporate and travel to a condenser.

- Advantages: Enhances film uniformity and efficiency, especially effective for high-viscosity materials.

- Applications: Ideal for separating complex mixtures and purifying substances with high boiling points, such as high-molecular-weight polymers and certain bioactive compounds.

Advertisements

Uses:

- Purification of vitamins, fatty acids, and other high molecular weight compounds.

- Distillation of sensitive pharmaceutical products.

- Used in the food and cosmetic industries.

Merits:

- Suitable for high molecular weight and thermally sensitive compounds.

- Minimizes thermal decomposition due to low operating temperatures.

- High purity of the distilled product.

Demerits:

- Complex and expensive setup.

- Requires precise control of operating conditions.

- Not suitable for large-scale continuous operations.

Advertisements