Principle of Plate & Frame Filter

- The plate and frame filter press operates on the principle of pressure filtration.

- A slurry (mixture of solid particles and liquid) is pumped into the press, and pressure is applied to separate the solid particles from the liquid.

Construction of Plate & Frame Filter

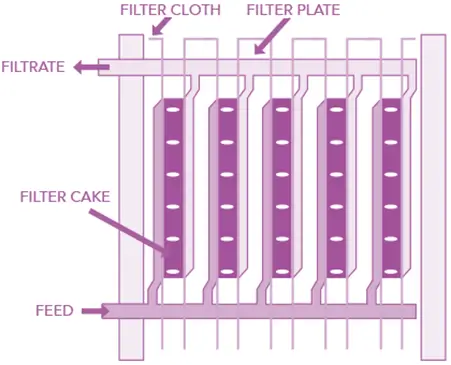

- Filter Plates: Flat plates with grooved surfaces to allow liquid to flow.

- Filter Frames: Hollow frames that hold the slurry.

- Filter Cloth: Porous cloths that cover the plates to retain solids.

- Hydraulic System: Applies pressure to compress the plates and frames.

- Feed Pump: Pumps the slurry into the press.

The plates and frames are arranged alternately and held together in a sturdy frame. The filter cloth is placed between each plate and frame to form a seal.

Advertisements

Working

- The slurry is pumped into the frames.

- Pressure is applied using a hydraulic system, compressing the plates and frames.

- The liquid passes through the filter cloth, leaving the solid particles behind to form a filter cake.

- The filtrate is collected and drained off, while the solid cake remains between the plates.

- Once the cycle is complete, the press is opened, and the filter cake is removed.

Uses

- Pharmaceutical industry

- Food and beverage industry

- Chemical manufacturing

- Wastewater treatment

Merits

- High filtration efficiency.

- Produces a dry filter cake.

- Suitable for small to medium batches.

Demerits

- Labor-intensive.

- High maintenance cost.

- Not suitable for continuous operation.

Click Here to Watch the Best Pharma Videos

Advertisements