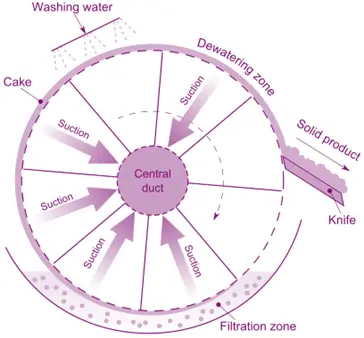

Principle of Rotary Drum Filter

- The rotary drum filter operates on the principle of vacuum filtration, where a vacuum is applied inside the drum to draw liquid through the filter medium, leaving solids behind.

Construction of Rotary Drum Filter

Advertisements

- Rotary Drum: A rotating cylindrical drum covered with a filter cloth.

- Vacuum System: Creates a vacuum inside the drum.

- Slurry Tank: Contains the slurry to be filtered.

- Discharge System: For collecting filtrate and removing filter cake.

- Agitator: Keeps the slurry in suspension.

Working

- The drum rotates partially submerged in the slurry tank.

- A vacuum is applied inside the drum, drawing liquid through the filter cloth.

- Solids are retained on the outside of the drum, forming a filter cake.

- As the drum rotates, the filter cake is dried by air or other means.

- The cake is removed by a scraper or other mechanical means.

- The filtrate is collected and drained off.

Advertisements

Uses

- Mineral processing

- Food industry (e.g., sugar refining)

- Wastewater treatment

- Pharmaceutical industry

Merits

- Continuous operation.

- Suitable for large-scale filtration.

- Produces a relatively dry filter cake.

Advertisements

Demerits

- High initial cost.

- Requires significant space.

- Not suitable for very fine particles.

- Maintenance can be complex.