Principles of Semi-Continuous Centrifuge

- The semi-continuous centrifuge operates on the principle of centrifugal force to separate components of a slurry based on density differences.

- Unlike batch centrifuges, semi-continuous centrifuges allow for periodic discharge of solids without stopping the entire process, providing a balance between continuous and batch processing.

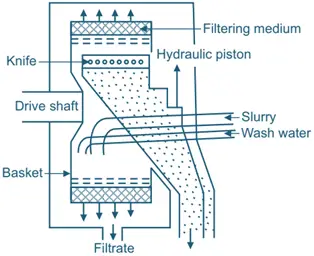

Construction of Semi-Continuous Centrifuge

- Rotor/Basket: Typically, a solid-walled or perforated drum that rotates at high speeds.

- Feed System: Mechanism to continuously feed the slurry into the centrifuge.

- Discharge Mechanism: Automated system to periodically discharge accumulated solids without stopping the centrifuge.

- Drive System: Motor and spindle to spin the rotor.

- Control Panel: For adjusting operational parameters like speed, feed rate, and discharge intervals.

- Housing: Outer casing to contain the process and collect separated liquids.

Working

- Feeding: The slurry is continuously fed into the rotating drum.

- Separation: The centrifugal force separates the components, with denser solids moving to the outer wall and liquids moving toward the center.

- Intermittent Discharge: At preset intervals, the solids are discharged through an automated system (such as a scraper or discharge valve) without stopping the centrifuge.

- Continuous Collection: The separated liquid flows out continuously through an outlet.

Uses

- Chemical and pharmaceutical industries for the separation of crystalline or precipitated solids from liquids.

- Food and beverage industry for juice clarification and sugar crystallization.

- Wastewater treatment for sludge dewatering.

- Oil industry for separating oil and water from solids.

Merits

- Combines the benefits of batch and continuous centrifuges.

- Reduces downtime as solids are discharged intermittently without stopping the process.

- High efficiency in solid-liquid separation.

- Can handle large volumes with consistent throughput.

Demerits

- More complex construction and operation compared to batch centrifuges.

- Higher initial cost due to additional automation.

- Requires precise control and maintenance to ensure proper intermittent discharge.

- Limited to applications where periodic discharge is acceptable.