Principles of Super Centrifuge

- The super centrifuge, also known as an ultracentrifuge, operates on the principle of generating extremely high centrifugal forces to separate particles based on very small differences in density.

- These centrifuges can achieve speeds much higher than conventional centrifuges, enabling the separation of sub-micron particles and molecules.

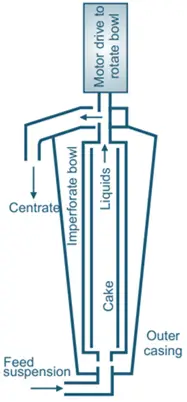

Construction of Super Centrifuge

- Rotor/Bowl: A high-strength rotor that can withstand extremely high speeds.

- Drive System: A powerful motor and spindle designed for ultra-high-speed rotation.

- Vacuum System: Often includes a vacuum chamber to reduce air resistance and heating due to friction.

- Cooling System: Maintains temperature control to prevent overheating during high-speed operation.

- Control System: Advanced control panel for precise adjustment of speed, temperature, and other parameters.

- Safety Enclosure: A robust housing to contain the rotor and ensure safety during operation.

Advertisements

Working

- Loading: The sample is loaded into the rotor or sample tubes, which are then placed in the centrifuge.

- Acceleration: The centrifuge accelerates to ultra-high speeds, generating enormous centrifugal forces.

- Separation: Particles are separated based on density differences, with denser particles moving to the outer edge of the rotor and lighter particles staying closer to the center.

- Deceleration: The centrifuge decelerates after the desired separation is achieved, and the separated components are collected.

Advertisements

Uses

- Biotechnology and molecular biology for the separation of viruses, proteins, nucleic acids, and other macromolecules.

- Pharmaceutical industry for purifying drugs and vaccines.

- Nanotechnology for separating nanoparticles.

- Analytical laboratories for sedimentation analysis and density gradient separation.

Merits

- Capable of separating extremely small particles and molecules.

- Provides high-resolution separation based on small density differences.

- Essential for advanced research and analytical applications.

- High precision and reproducibility.

Advertisements

Demerits

- Very high initial cost and operational expenses.

- Requires specialized training for operation and maintenance.

- Limited to specific applications where ultra-high-speed separation is necessary.

- Potential for rotor damage or sample disruption at very high speeds.