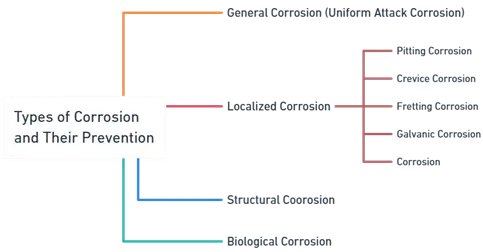

Understand the different types of corrosion—like uniform, galvanic, pitting, and crevice—and learn effective prevention methods such as coatings, cathodic protection, andmaterial selection.“

General Corrosion (Uniform Attack Corrosion)

- Definition: Corrosion that occurs uniformly over a large surface area.

- Example: Rusting of iron in the atmosphere.

Prevention:

- Use of corrosion-resistant materials (e.g., stainless steel).

- Application of protective coatings (e.g., paint, galvanization).

- Regular maintenance and cleaning to remove corrosive agents.

- Use of corrosion inhibitors in the environment.

Advertisements

Localized Corrosion

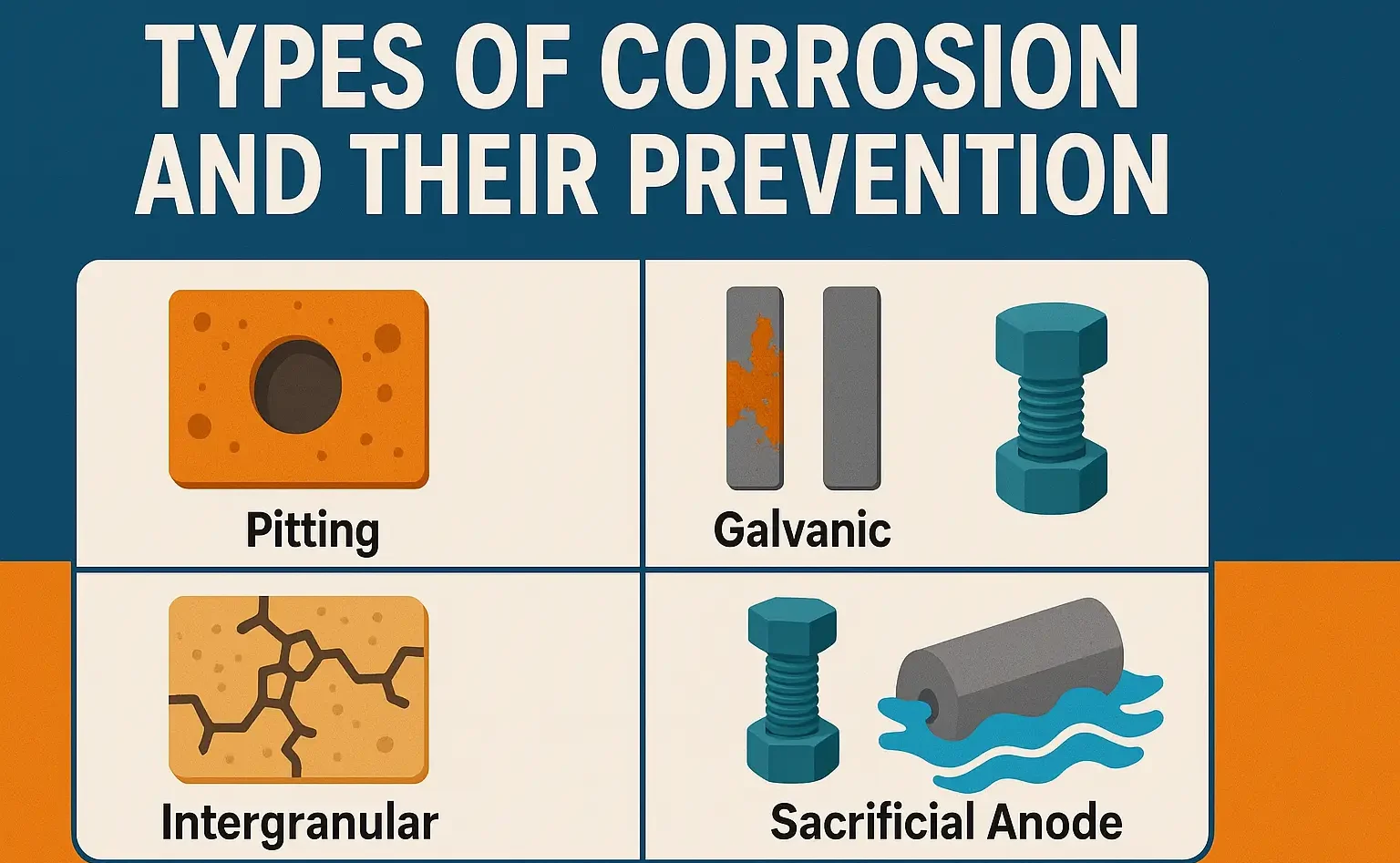

Pitting Corrosion:

- Definition: Formation of small, localized holes or pits on the surface.

- Example: Pitting of stainless steel in chloride-rich environments.

-

Prevention:

- Use of materials resistant to pitting (e.g., high-alloy stainless steels).

- Application of protective coatings.

- Control of the environment (e.g., reducing chloride ion concentration).

Crevice Corrosion:

- Definition: Occurs in confined spaces where the access of the working fluid is limited.

- Example: Corrosion under gaskets, washers, or deposits.

-

Prevention:

- Proper design to eliminate crevices.

- Use of welds instead of rivets or bolts.

- Regular cleaning to remove deposits.

Fretting Corrosion:

- Definition: Caused by repeated cyclic rubbing between two surfaces.

- Example: Corrosion at contact points in machinery due to vibration.

-

Prevention:

- Lubrication to reduce friction.

- Use of anti-fretting coatings.

- Designing to minimize relative motion between surfaces.

Galvanic Corrosion:

- Definition: Occurs when two different metals are in electrical contact in a corrosive environment.

- Example: Corrosion of a steel pipe connected to a copper fitting.

-

Prevention:

- Use of metals with similar electrochemical potentials.

- Electrical insulation between dissimilar metals.

- Application of protective coatings.

- Use of sacrificial anodes.

Corrosion Fatigue:

- Definition: Accelerated cracking due to the combined effect of cyclic stress and a corrosive environment.

- Example: Cracking of metal components in aircraft due to repeated stress and exposure to the environment.

-

Prevention:

- Reducing cyclic stresses through design modifications.

- Use of corrosion-resistant materials.

- Application of protective coatings.

- Avoiding environments that promote corrosion.

Advertisements

Structural Corrosion

- Definition: Affects the structural integrity of materials, leading to weakening and potential failure.

- Example: Deterioration of steel beams in bridges, causing reduced load-bearing capacity.

-

Prevention:

- Use of corrosion-resistant materials.

- Application of protective coatings.

- Regular inspections and maintenance.

- Cathodic protection.

Biological Corrosion

- Definition: Caused by the activity of microorganisms, such as bacteria, algae, or fungi, which induce or accelerate corrosion processes.

- Example: Corrosion of metal surfaces in pipelines due to sulfate-reducing bacteria.

-

Prevention:

- Use of biocides to control microbial growth.

- Regular cleaning and maintenance to remove biofilms.

- Use of materials resistant to biological attack.

- Coatings that inhibit microbial attachment.

Click Here to Watch the Best Pharma Videos

Advertisements